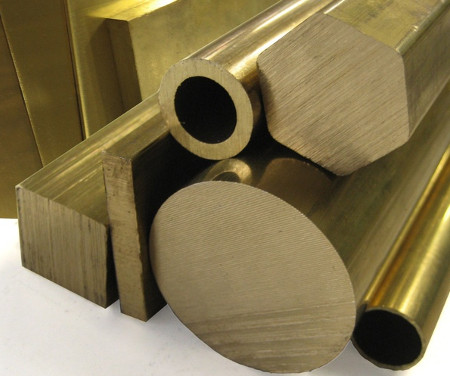

Brass

Brass is an alloy of copper and zinc; the proportions of zinc and copper can be varied to create a range of brasses with varying properties. By comparison, bronze is principally an alloy of copper and tin.Bronze does not necessarily contain tin, and a variety of alloys of copper, including alloys with arsenic, phosphorus, aluminium, manganese, and silicon, are commonly termed “bronze”. The term is applied to a variety of brasses and the distinction is largely historical, both terms having a common antecedent in the term latten. Brass is a substitutional alloy. It is used for decoration for its bright gold-like appearance; for applications where low friction is required such as locks, gears, bearings, doorknobs, ammunition casings and valves; for plumbing and electrical applications; and extensively in musical instruments such as horns and bells for its acoustic properties. It is also used in zippers. Brass is often used in situations where it is important that sparks not be struck, as in fittings and tools around explosive gases.

| Chemical Composition of Brasses |  |

||||

| Material | Normal Composition | Nearest Relevant Composition Specification | |||

| BS : 2870 | ISO | JIS | |||

| 95/5 Cap Copper |

95% Cu, 5% Zn | CZ 125 | Cu Zn 5 | H 3100 C 2100 |

|

| 90/10 Guilding Metal |

90% Cu, 10% Zn | CZ101 | Cu Zn 10 426/1 |

H 3100 C 2200 |

|

| 85/15 Guilding Metal |

85% Cu, 15% Zn. | CZ102 | Cu Zn 15 426/1 |

H 3100 C 2300 |

|

| 80/20 Brass |

80% Cu, 20% Zn. | CZ103 | Cu Zn 20 426/1 |

H 3100 C 2400 |

|

| 70/30 (Cartridge Brass) |

70% Cu, 30% Zn. | CZ106 | Cu Zn 30 426/1 |

H 3100 C 2600 |

|

| 60/35 (2 and 1 Brass) |

65% Cu, 35% Zn. | CZ107 | Cu Zn 35 426/1 |

H 3100 C 2680 |

|

| 63/37 (Common Brass) |

63% Cu, 37% Zn | CZ108 | Cu Zn 37 426/1 |

H 3100 C 3560 |

|